No products in the cart.

How to Decide Board Thickness for Shipping vs Retail Boxes

Choosing the right cardboard thickness is one of the most practical decisions in packaging design, affecting protection, cost, print quality, and product value. Objectively, express delivery and shipping boxes focus on providing strength and protection during transit, thus resisting pressure, stacking, drops, and rough handling. Retail packaging is primarily used for display boxes and showcases. It places greater emphasis on appearance, aesthetics, and display printing. Understanding corrugated paper grades and GSM cardboard can help you choose the cardboard thickness that best protects your product while optimizing costs.

If we take functionality as the starting point, what will packaging experience?

Shipping boxes:

What type of products are the shipping boxes used to package? Are the products pressure-resistant? Are the products fragile? Will the boxes be stacked on pallets? How many boxes will be stacked on each pallet? What is the weight of each box? Will the products undergo long-distance transportation? Will they frequently experience rough handling during transport?

Retail boxes:

Is the box for inexpensive everyday items or for exquisite gifts? Is the product heavy or made of fragile glass? Does it need to convey a high-end experience and exquisite craftsmanship?

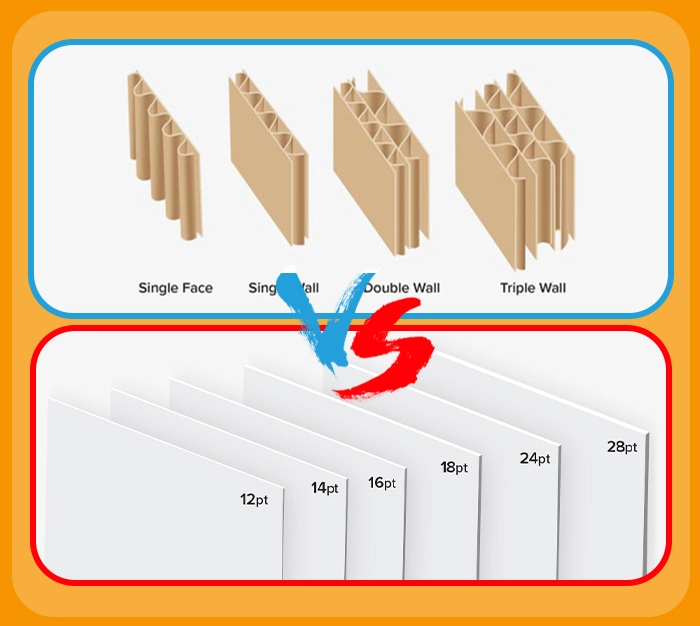

Understanding the thickness of corrugated paper and its applications

| Type | Thickness | Application |

| E Flute | 1.1-2mm | Good for jewelry/cosmetic/apparel/pizza packaging, 90 flutes per foot. |

| B Flute | 2.5-3mm | Good for canned food/retail packaging, 49 flutes per foot. |

| C Flute | 3.5-4mm | Good for glass/furniture/dairy packaging, 41 flutes per foot. |

| A Flute | 4.5-5mm | Good for fragile/delicate items, 36 flutes per foot. |

| BC Flute | 6-7mm | Good for glass/small furniture/toys/small musical instrument packaging. |

| AB Flute | 8-9mm | Good for heavy product packaging such as rubber boats/home appliances, cargo storage, and moving. |

| BE Flute | 3.6-5mm | Good for apparel/cosmetic/jewelry/bag/food packaging. |

Above data determine if you need single-wall corrugated (one flute + two liners), double-wall (two flutes + three liners), or even triple-wall board. For heavy, high-stack, or long-distance shipments you’ll commonly step up to double- or triple-wall constructions to gain compression and puncture resistance. For lighter, low-risk shipments a single-wall in the right flute (B, C, or E) can be both protective and economical.

Flute type and wall construction control thickness and behavior. Corrugated thickness isn’t just “more mm = stronger.” Flute profile (A, B, C, E, F) controls cushioning, compression, and crush resistance: larger flutes (A, C) give cushioning and vertical compression strength for heavy items; smaller flutes (B, E, F) offer better crush resistance and flatter surfaces for printing and die-cutting. Combining flutes into double- or triple-wall boards blends cushioning, puncture resistance, and stacking strength. So when you specify “thickness” for shipping boxes, think in terms of flute grade + number of walls rather than only millimeters.

The thickness of a retail box depends on market positioning, budget, and product type

First, GSM measures weight per unit area(g/㎡), not directly equivalent to thickness(mm). Even with the same GSM, differences in structure and fiber density can lead to variations in thickness. The cardboard used in commonly used cardboard packaging boxes is approximately 250-400gsm.

- 250-300gsm: This is a lightweight type, often used for packaging low-priced, disposable products such as soap and toothpaste. It has lower requirements for product aesthetics, rigidity, and printing quality.

- 300-350gsm: This falls into the middle range and is commonly used for packaging of small to medium-sized daily necessities, cosmetics, food, and other products. It requires a certain level of durability, rigidity, aesthetic appeal, and high printability.

- 350-400gsm: Commonly used for heavier products and larger sizes, such as glass jars of cosmetics, hoodies, wines, and candles.

- 400gsm and above: A single sheet of paper cannot achieve a greater thickness, so two sheets of the same or different GSM are usually glued together to achieve the desired thickness. For example: 250gsm + 300gsm = 550gsm

For exquisite gift boxes, we often use rigid board, which is indicated by its thickness(mm). The thicker the rigid board, the higher its rigidity and stiffness, and the better its load-bearing capacity. Cost is positively correlated with thickness, so the thicker the cardboard, the higher the cost.

- 5-1.8mm: Typically used for smaller gift boxes, such as jewelry packaging.

- 8-2.5mm: Suitable for medium-sized gift packaging, such as cosmetic sets, jewelry sets, fine chocolates, wigs, shirts, leather shoes, etc.

- 5-3.5mm: Suitable for heavier products, exquisite gifts, and fragile items, such as vases, wine bottles, teacups, home textiles, and baby products.

There’s never a standard answer to choosing the right thickness; cost, rigidity, aesthetics, and practicality all need to be considered. Contact us for the most suitable packaging plan for your product.

Latest News

How to palletise Paper Boxes for Export Shipping?

November 13, 2025

How to Craft Unboxing Experiences Using Paper Packaging

November 7, 2025

How to Use Packaging as A Marketing Channel for Repeat Purchases

November 6, 2025

How to Choose Between Stock Boxes and Fully Custom Printed Boxes

November 5, 2025