No products in the cart.

How to Design Die-lines for a Custom Box

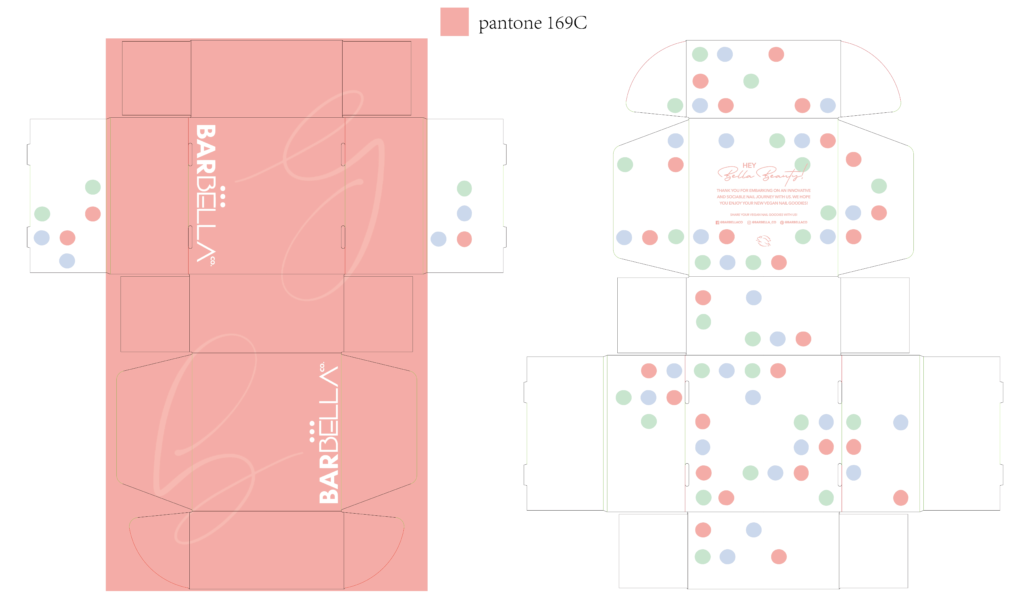

Why does custom packaging require a dedicated die-line?

Die-lines are fundamental to packaging design. Designers must mark die lines, fold lines, indentations, perforations, and gluing positions on a flat surface. This is essential for converting a flat document into a physical box. Accurate die lines prevent issues like inaccurate printing, incorrectly cut graphics, assembly errors, and dimensional mismatches with the product.

According to the box type classification, there are usually the following styles:

The following are common general-purpose die lines. We also offer other sizes and improved styles based on customer needs. If you need to adjust the thickness or material, we will also change the die line size to suit the product size.

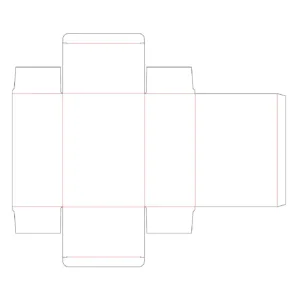

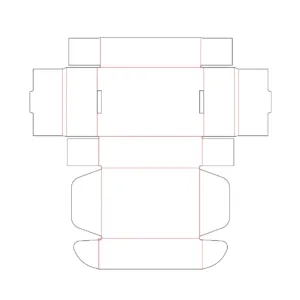

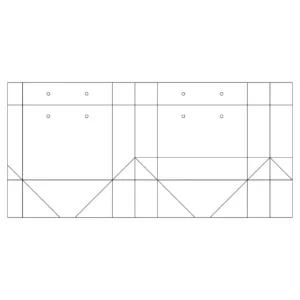

Tuck End Box

- Feature:The top and bottom ends can be opened, and need to be folded by yourself when closed.

- Application:Cosmetic, medicine, skin care, cereal, makeup, soap, chocolate, phone case etc. lightweight products.

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated recycled board (CRB), coated unbleached kraft (CUK) / virgin kraft, corrugated

- Advantage:Simple process, low minimum order quantity, wide application range and low price.

- Disadvantage:Limited load-bearing capacity, not exquisite enough.

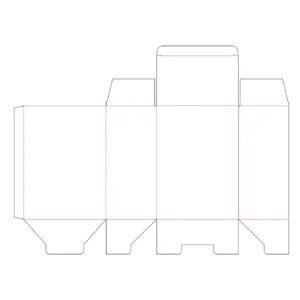

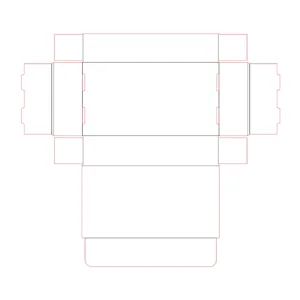

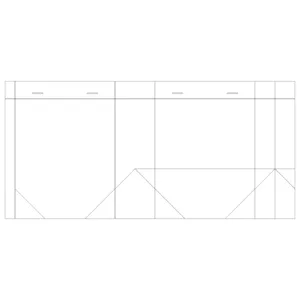

Snap Lock Box

- Feature:Usually only the top can be opened, and the bottom is semi-closed, and you need to plug in several sockets to close it yourself.

- Application:Cosmetic, medicine, skin care, cereal, makeup, soap, chocolate, phone case etc. Lighter weight products.

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated recycled board (CRB), coated unbleached kraft (CUK) / virgin kraft, corrugated

- Advantage:Simple process, low minimum order quantity, wide application range and low price.

- Disadvantage: Limited load-bearing capacity, not exquisite enough.

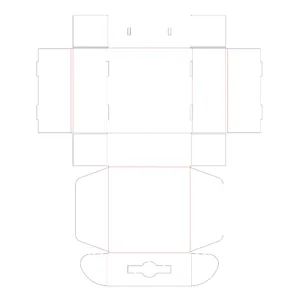

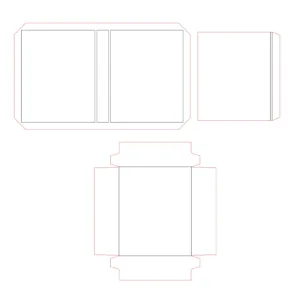

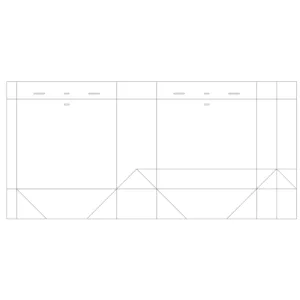

Tuck Top Auto Bottom Box

- Feature:It can only be opened from the top, and the bottom is semi-glued and will close automatically during the folding process.

- Application:Cosmetic, medicine, skin care, cereal, makeup, soap, chocolate, phone case etc. Lighter weight products.

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated recycled board (CRB), coated unbleached kraft (CUK) / virgin kraft, corrugated

- Advantage:Simple process, low minimum order quantity, wide application range and low price.

- Disadvantage: Limited load-bearing capacity, not exquisite enough.

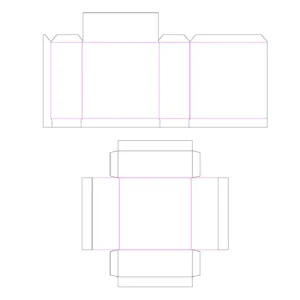

Tray Box

- Feature:The way to open it is to pull it left and right. It is shipped in one piece and needs to be folded into shape when you receive it.

- Application:Perfume, Socks, Underwear, Cookie, Candy, Hair Clip, Hair Scrunchies, Glasses, Makeup Tools etc..

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated recycled board (CRB), coated unbleached kraft (CUK) / virgin kraft.

- Advantage:Simple process, low minimum order quantity, wide application range.

- Disadvantage: Uses a lot of paper and is troublesome to fold.

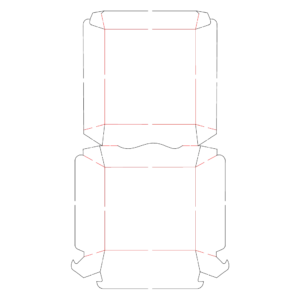

Airplane Box

- Feature:It is one-piece molded and needs to be folded by yourself when used, but no matter what material it is made of, it is relatively strong.

- Application:Transportation of jewelry, cosmetic, skin care, apparel, gift, home textiles, food, glasses, toiletries and other products.

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated recycled board (CRB), coated unbleached kraft (CUK) / virgin kraft, corrugated

- Advantage:Simple workmanship, simple operation, strong load-bearing capacity and wide applicability.

- Disadvantage: The shipping volume is larger, the price of customization is slightly higher, and the minimum order quantity is larger, not elegant enough.

Rigid Box

- Feature:The main body is made of thicker paper board and the surface is covered with a layer of printing paper. The overall structure is hard and delicate.

- Application:Jewelry, Cosmetic, Skin Care, Wig, Beauty Instrument, Liquor, Home Textiles, Gift etc..

- Availablepaperboard: Rigid Board.

- Advantage:Exquisite and strong.

- Disadvantage: High price, large volume and heavy weight during transportation, high minimum order quantity.

Shoes Box

- Feature:Flip opening with only outside printing usually.

- Application:Leather shoes, sneakers, high heels, sandals, slippers, boots, etc..

- Availablepaperboard: Corrugated Paperboard.

- Advantage:Simple process, it can be used for transportation, and it is pressure-resistant.

- Disadvantage: Troublesome to fold, high minimum order quantity, large shipping volume.

Paper Bag

- Feature:Usually there are two styles-cardboard and kraft paper.

- Application:Jewelry, Cosmetic, Skin Care, Apparel, Food, Gift etc..

- Availablepaperboard: Solid bleached sulfate (SBS), folding box board (FBB), coated unbleached kraft (CUK) / virgin kraft.

- Advantage:There are many materials and handles to choose from, and various crafts can be customized. There are many derivative styles and they are quite exquisite.

- Disadvantage: The minimum order quantity is high, the labor cost is high, the workmanship is complicated, it is easy to be scratched after coated, and the waste rate in the production process is high.

Food Box

The following are several commonly used types of food packaging boxes. The styles are relatively basic and will be improved or adjusted according to everyone’s needs.

Special Box

Special box types are currently very popular because people still want more special effects besides the basic packaging of their products. The following special box types are suitable for any product regardless of material or size.

As a manufacturer of customized paper packaging boxes, we have been committed to providing you with die-cutting lines and 3D models for free. If you need them, please contact us.

Latest News

How to palletise Paper Boxes for Export Shipping?

November 13, 2025

How to Craft Unboxing Experiences Using Paper Packaging

November 7, 2025

How to Use Packaging as A Marketing Channel for Repeat Purchases

November 6, 2025

How to Choose Between Stock Boxes and Fully Custom Printed Boxes

November 5, 2025