No products in the cart.

How to Make Your Custom Paper Packaging Stand Out with Special Finishes

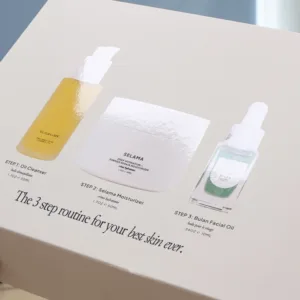

If you want the box to look special or have a very unique style, in addition to working on the box shape and material, you can also use other special crafts to make the box stand out.

Currently, the most commonly used special processes in paper packaging are lamination, hot stamping, embossing, debossing, textured and spot UV.

Lamination

The lamination process is a process that is done after the paper is printed. It not only fixes the color, but also makes the original box stronger. Paper packaging boxes are originally very brittle and not very ductile. The lamination increases the flexibility and firmness of the box, so that the box will not break during the folding process.

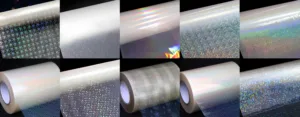

But most people only know that lamination are transparent, and there are only differences between glossy and matte. But in fact, the lamination also has a variety of colors and patterns.

As shown in the picture above, these films with special patterns are also commonly used in printing and packaging. Most of them are holographic colors and will reflect light as the light changes.

Hot Stamping

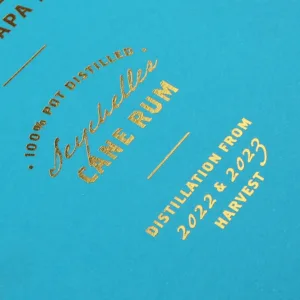

This is one of the most common processes that is widely known to the public. I believe you must have seen this process on various packaging. Shopping malls, supermarkets and on the packaging of various branded products. Of course, this craft can not only be used on logos, but also on linear patterns, borders, and even large-area patterns. The following pictures show you the different ways of using hot stamping.

|  |  |

| Pattern | Text | Border |

Fortunately, the color of hot stamping is not so single. In addition to gold and silver, there are various other colors, such as red, blue, orange, green, holographic, and even black and white. At the same time, on the basis of hot stamping color, some colors also has patterns.

For the color of hot stamping, we have a catalog of stamping colors, if you customize paper packaging in Qingdao Yilucai Packaging Co., ltd, then the color of stamping will not be a problem.

Embossing

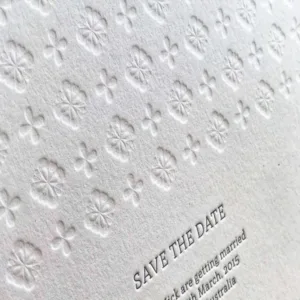

This is a 3D process, also known as relief, which uses pressure to deform the paper and make it protrude outward.

This process is very interesting. For example, it can be used to emboss letters or patterns, and can be used together with hot stamping. Both the logo and the pattern can be colorless or colored, but believe me, if your box is pure color, the embossing process will be very special. Another example, if your box is printed with the product itself, then embossing the product pattern will make your product visually feel like it is about to come out.

Here is a example of embossing for your reference. Let’s play with packaging.

Debossing

The processing method of debossing is just the opposite of embossing. It uses a mold to press the paper down to create some dents and grooves. Compared with embossing, debossing seems more special. Few people use debossing to make logos, but more people choose to debossing some patterns. Hope the following cases can provide you with reference.

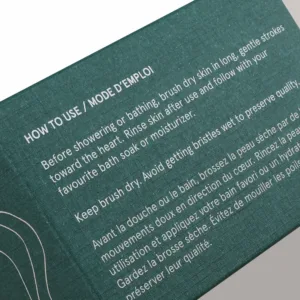

Textured

A process very similar to debossing, but debossing only supports small areas or partial patterns, while textured can be a large area, and the lines are fine and regular. Through textured, paper will look like fabric, leather and other materials.

This process is commonly used in jewelry packaging, clothing, shoes, bags, watches and other packaging, making ordinary paper boxes, paper bags and cards look more luxurious. We also have a catalogue on textured patterns, if you are interested in textured packaging, please contact us.

Spot UV

Spot UV is a special printing technology that uses ultraviolet light to fix ink on printed products to highlight key text or patterns. This enhances the surface texture and visual effect. The commonly used spot UV effect is glossy, but there are also styles such as matte and frosted. It can be implemented after the printed product is laminated, or it can be done directly on the printed product.

The above six processes can be used in combination to present various effects. Everyone is welcome to customize their own packaging in Qingdao Yilucai Packaging Co., ltd.

Latest News

How to palletise Paper Boxes for Export Shipping?

November 13, 2025

How to Craft Unboxing Experiences Using Paper Packaging

November 7, 2025

How to Use Packaging as A Marketing Channel for Repeat Purchases

November 6, 2025

How to Choose Between Stock Boxes and Fully Custom Printed Boxes

November 5, 2025