No products in the cart.

- Home

- Options Library

- EPE

Expanded Polyethylene (EPE) Foam Insert

Custom molded polyethylene (EPE) foam inserts are the perfect choice for protecting your products against damage due to its high shock absorbent characteristic. Thermoplastics like EPE are fully recyclable and can be easily reheated and reshaped.

- Lightweight and recyclable

- Shock absorbent material

- Custom-molded to your product

Overview

Expanded polyethylene (EPE) is a lightweight and durable thermoplastic. Made up of millions of tiny bubbles, EPE offers a lot of strength and rigidity for packaging a wide range of products. EPE can hold several items at once with very high shock absorption from heavy industrial materials to small and fragile items. EPE is also fully recyclable and can easily be melted and reshaped for a purpose beyond your product packaging. Our polyethylene foam inserts are available in a wide range of densities and colors.

Foam Comparison

| Density (kg/cm³) | Hardness | Overall Weight | Available Colors | |

|---|---|---|---|---|

| Polyurethane Foam (PU) | 18 – 45 kg/m³ | 38/45/60 Shore C | Light | Black, White, Grey, Yellow |

| Polyethylene Foam (EPE) | 20 – 120 kg/m³ | 30 – 38 Shore C | Light | Black, White, Pink |

| Ethylene-Vinyl Acetate Foam (EVA) | 33 – 280 kg/m³ | 15 – 80 Shore C | Heavy | Black, White |

Foam Fabrication Methods

Water Jet Cut

Process of cutting material with a high-pressure jet of water—ideal for producing extremely accurate shapes.

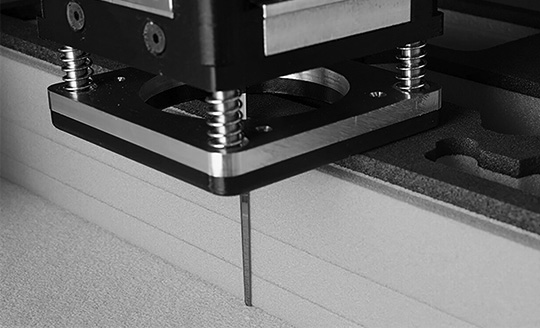

Knife/Router Cut

Process of cutting material using a router bit or knife—ideal for prototyping due to its imprecise finish.

Die Cut

Process of cutting material using a series of dies—ideal for simple two-dimensional cutouts.

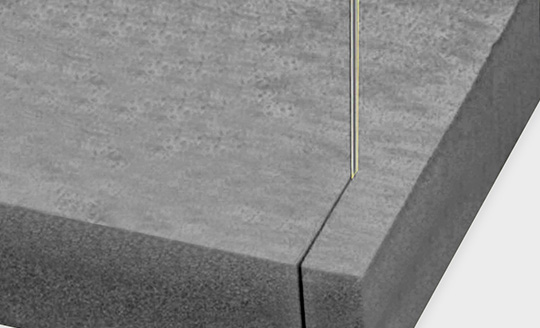

Wire Cut

Process of cutting material using a heated metal wire to melt and vaporize foam to create clean, crisp cuts.

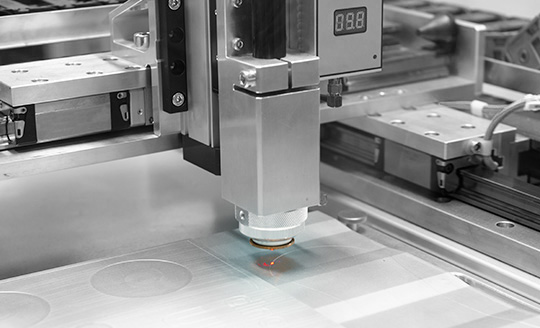

Laser Cut

Process of cutting material using a high-power laser beam to cut and vaporize foam for smooth edges.