No products in the cart.

- Home

- Options Library

- EVA

Ethylene-Vinyl Acetate (EVA) Foam Insert

Custom molded ethylene-vinyl acetate (EVA) foam inserts is high-density foam popular for creating custom foam box inserts. Incredibly successful in providing protection and support to fragile products, EVA foam is commonly used for packaging electronics, glassware, or any luxury product.

- Dense and supportive

- High impact resistance

- Custom-molded to your product

Overview

Ethylene-Vinyl Acetate is a highly dense foam material that creates foam box inserts for luxury product packaging. EVA foam is incredibly versatile and is great at absorbing vibrations and impacts, making it ideal for packaging fragile or luxury products. In addition, it can bond well with adhesives making it convenient to create custom shapes and thicknesses to create the optimal support system for your product. This foam compared to other foam alternative like EPE or PU is the highest quality and adds immense value to the unboxing experience of your products. Our ethylene-vinyl foam inserts are available in a wide range of densities and colors.

Foam Comparison

| Density (kg/cm³) | Hardness | Overall Weight | Available Colors | |

|---|---|---|---|---|

| Polyurethane Foam (PU) | 18 – 45 kg/m³ | 38/45/60 Shore C | Light | Black, White, Grey, Yellow |

| Polyethylene Foam (EPE) | 20 – 120 kg/m³ | 30 – 38 Shore C | Light | Black, White, Pink |

| Ethylene-Vinyl Acetate Foam (EVA) | 33 – 280 kg/m³ | 15 – 80 Shore C | Heavy | Black, White |

Foam Fabrication Methods

Water Jet Cut

Process of cutting material with a high-pressure jet of water—ideal for producing extremely accurate shapes.

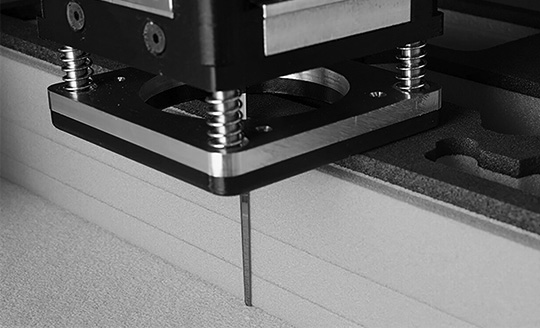

Knife/Router Cut

Process of cutting material using a router bit or knife—ideal for prototyping due to its imprecise finish.

Die Cut

Process of cutting material using a series of dies—ideal for simple two-dimensional cutouts.

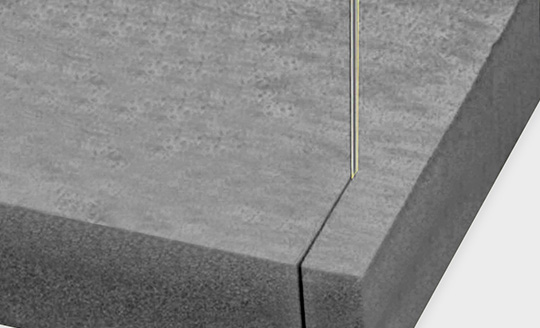

Wire Cut

Process of cutting material using a heated metal wire to melt and vaporize foam to create clean, crisp cuts.

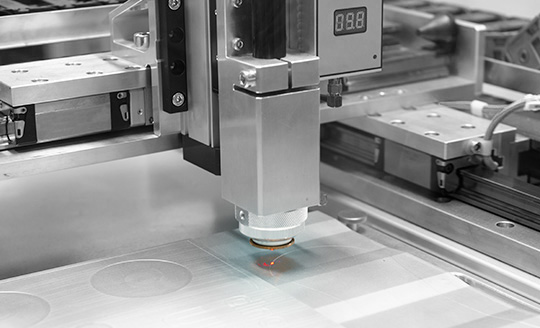

Laser Cut

Process of cutting material using a high-power laser beam to cut and vaporize foam for smooth edges.