No products in the cart.

- Home

- Options Library

- Foam

Polyurethane (PU) Foam Insert

Custom molded polyurethane (PU) foam inserts are the perfect choice for protecting your products against damage due to its high shock absorbent characteristic while creating a luxury look and feel. In addition, PU foam is an excellent choice for its lightweight and compressible (easy to store) nature.

- Lightweight and compressible for easy storage

- Shock absorbent material

- Custom-molded to your product

Overview

PU, short for polyurethane, is a kind of open-cell foam material that is lightweight and more compressible than other foam alternatives, making it very versatile in many packaging applications. In addition, due to its soft characteristic, PU foam has high shock absorbency, turning this material a standard selection among many industries looking for added protection. Our polyurethane foam inserts are available in a wide range of densities and colors.

Foam Comparison

| Density (kg/cm³) | Hardness | Overall Weight | Available Colors | |

|---|---|---|---|---|

| Polyurethane Foam (PU) | 18 – 45 kg/m³ | 38/45/60 Shore C | Light | Black, White, Grey, Yellow |

| Polyethylene Foam (EPE) | 20 – 120 kg/m³ | 30 – 38 Shore C | Light | Black, White, Pink |

| Ethylene-Vinyl Acetate Foam (EVA) | 33 – 280 kg/m³ | 15 – 80 Shore C | Heavy | Black, White |

Foam Fabrication Methods

Water Jet Cut

Process of cutting material with a high-pressure jet of water—ideal for producing extremely accurate shapes.

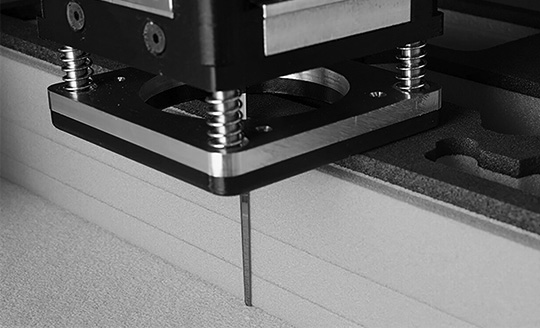

Knife/Router Cut

Process of cutting material using a router bit or knife—ideal for prototyping due to its imprecise finish.

Die Cut

Process of cutting material using a series of dies—ideal for simple two-dimensional cutouts.

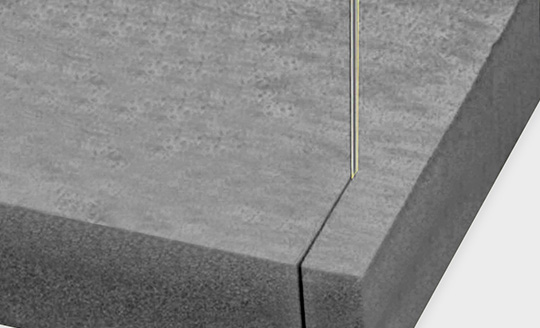

Wire Cut

Process of cutting material using a heated metal wire to melt and vaporize foam to create clean, crisp cuts.

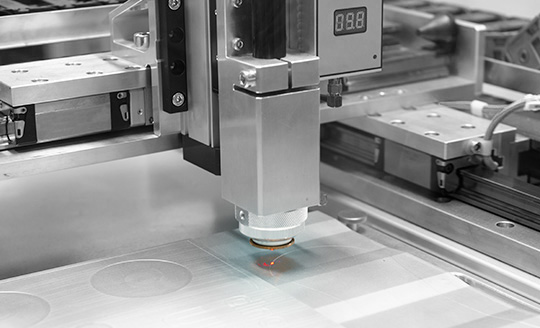

Laser Cut

Process of cutting material using a high-power laser beam to cut and vaporize foam for smooth edges.