No products in the cart.

- Home

- Options Library

- Kemi White Board

Kemi White Board

Kemi White Board features a semi-gloss-coated brilliant white C1S linerboard on one side, perfect for high-quality printing and finishing capabilities. In addition, this material has a semi-gloss coating pre-applied making your prints require no additional coatings to get a semi-gloss finish. However, Kemi is more expensive than its mottled white counterpart.

- Brilliant semi-gloss coated white surface

- Printed colors appear more vibrant

- More expensive than mottled white

Best Used With

Overview

Clay Coated (Kemi) White Board: Previously described as ‘deluxe white,’ Kemi White is a brand of white-top board, much like Band-Aid is a brand of bandages. The clay coated, white surface of this liner board offers premium printing quality, with a slightly glossy, smooth-finish, making it ideal for retail applications such as POP displays. Kemi board the only corrugated board that is clay coated and has a unique and distinct advantage for digital printing compared to mottled white. Thanks to the clay coated surface, inks are less likely to sink into the board, so the colors will pop and be more vibrant.

Corrugated Board Process

Corrugated Board Process

Corrugated Board Performance

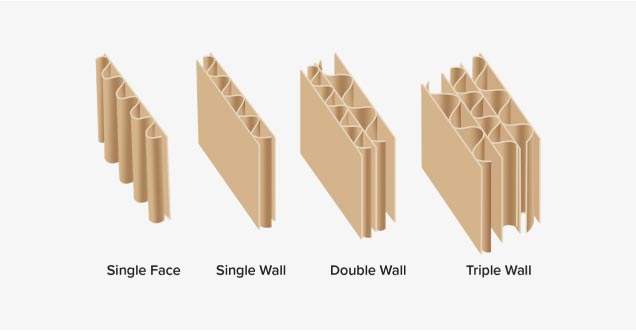

Single Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 125 lbs/sq in | 23 lbs/in | 52 lbs/m sq ft | 20 lbs | 40 in |

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 175 lbs/sq in | 29 lbs/in | 75 lbs/m sq ft | 50 lbs | 60 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

| 250 lbs/sq in | 40 lbs/in | 111 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 44 lbs/in | 138 lbs/m sq ft | 95 lbs | 95 in |

| 350 lbs/sq in | 55 lbs/in | 180 lbs/m sq ft | 120 lbs | 105 in |

Double Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 200 lbs/sq in | 42 lbs/in | 92 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 48 lbs/in | 110 lbs/m sq ft | 100 lbs | 95 in |

| 350 lbs/sq in | 51 lbs/in | 126 lbs/m sq ft | 120 lbs | 105 in |

| 400 lbs/sq in | 61 lbs/in | 180 lbs/m sq ft | 140 lbs | 110 in |

| 500 lbs/sq in | 71 lbs/in | 222 lbs/m sq ft | 160 lbs | 115 in |

| 600 lbs/sq in | 82 lbs/in | 270 lbs/m sq ft | 180 lbs | 120 in |

Triple Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 700 lbs/sq in | 67 lbs/in | 168 lbs/m sq ft | 240 lbs | 111 in |

| 900 lbs/sq in | 80 lbs/in | 222 lbs/m sq ft | 260 lbs | 115 in |

| 1100 lbs/sq in | 90 lbs/in | 264 lbs/m sq ft | 280 lbs | 120 in |

| 1300 lbs/sq in | 112 lbs/in | 360 lbs/m sq ft | 300 lbs | 125 in |

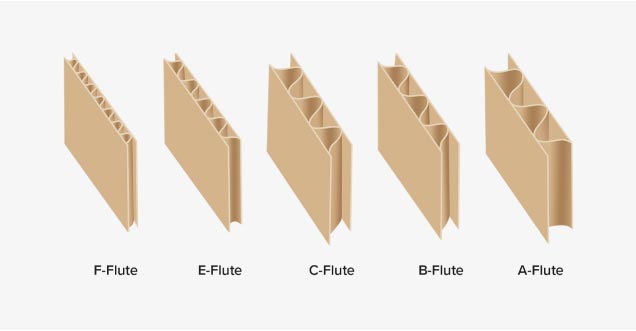

E-Flute

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

Corrugated Strength Tests

Edge Crush Test (ECT)

Force is applied perpendicular to the edge of the corrugated board until it buckles. The results provide accurate representation of the material’s strength, durability and stack resistance for heavier loads. The resulting value is shown in pounds per linear inch of load-bearing edge and is reported in ECT ratings.

Note: 32 ECT is the most commonly used for corrugated material.

Bursting Test

The burst test, otherwise known as the Mullen Test, challenges the durability of the corrugated fiberboard’s surface. The burst test determines the amount of force required to puncture the liner board. The resulting value is given in pounds per square inch.

Note: 200# means 200 pounds per square inch of force applied to the face of the liner board.