No products in the cart.

- Home

- Options Library

- Oyster White Board

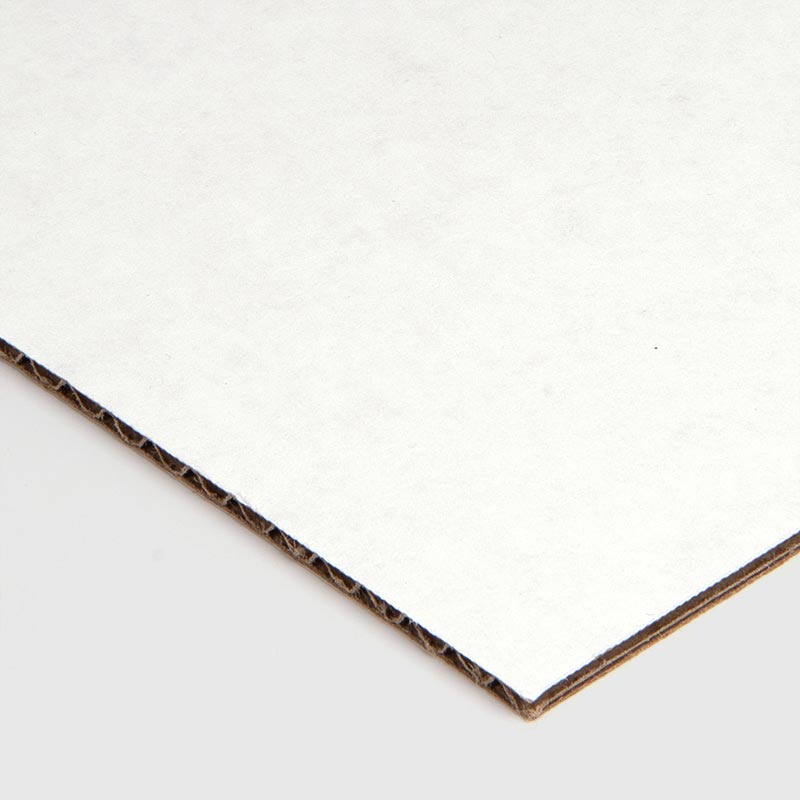

Oyster White Board

Oyster White Board or Mottled White Board features a clay-coated CCNB linerboard featuring an off-white surface with natural kraft undertones for moderate quality printing. In addition, this material is commonly chosen for being the most economical white corrugated option. For achieving higher quality color vibrancy, Bleached White or Kemi are the best choices.

- Off-white surface with natural kraft undertones

- Most economical option for white corrugated

- Highest recycled content option

Best Used With

Overview

Oyster board is the industry standard liner board for producing white corrugated packaging. Made from Kraft paper, this material features high recycled content making it up to 100% recyclable. The liner is a slightly off-white color, and because it is not fully bleached like typical white printing paper, the white maintains kraft brown undertones throughout. In most cases, it is the best choice for white corrugated packaging as it is cost-effective, readily available and offers more accurate color output when printed on. However, because of the more natural undertones, printing on this material will offer a ‘no gloss’ finish, making designs look more flat.

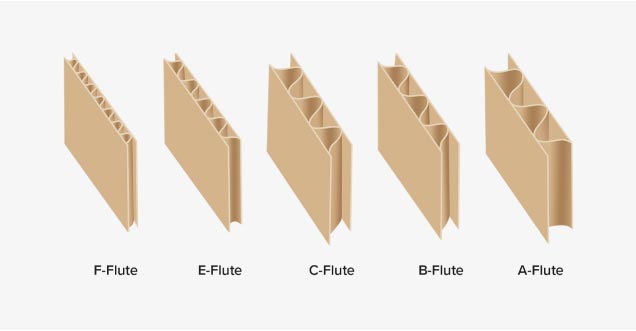

Corrugated Board Process

Corrugated Board Process

Corrugated Board Performance

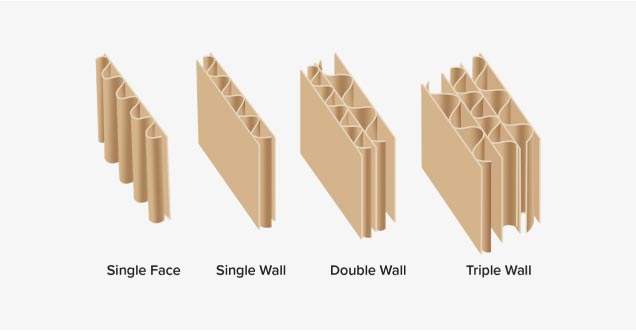

Single Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 125 lbs/sq in | 23 lbs/in | 52 lbs/m sq ft | 20 lbs | 40 in |

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 175 lbs/sq in | 29 lbs/in | 75 lbs/m sq ft | 50 lbs | 60 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

| 250 lbs/sq in | 40 lbs/in | 111 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 44 lbs/in | 138 lbs/m sq ft | 95 lbs | 95 in |

| 350 lbs/sq in | 55 lbs/in | 180 lbs/m sq ft | 120 lbs | 105 in |

Double Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 200 lbs/sq in | 42 lbs/in | 92 lbs/m sq ft | 80 lbs | 85 in |

| 275 lbs/sq in | 48 lbs/in | 110 lbs/m sq ft | 100 lbs | 95 in |

| 350 lbs/sq in | 51 lbs/in | 126 lbs/m sq ft | 120 lbs | 105 in |

| 400 lbs/sq in | 61 lbs/in | 180 lbs/m sq ft | 140 lbs | 110 in |

| 500 lbs/sq in | 71 lbs/in | 222 lbs/m sq ft | 160 lbs | 115 in |

| 600 lbs/sq in | 82 lbs/in | 270 lbs/m sq ft | 180 lbs | 120 in |

Triple Wall

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 700 lbs/sq in | 67 lbs/in | 168 lbs/m sq ft | 240 lbs | 111 in |

| 900 lbs/sq in | 80 lbs/in | 222 lbs/m sq ft | 260 lbs | 115 in |

| 1100 lbs/sq in | 90 lbs/in | 264 lbs/m sq ft | 280 lbs | 120 in |

| 1300 lbs/sq in | 112 lbs/in | 360 lbs/m sq ft | 300 lbs | 125 in |

E-Flute

| Min. Burst Strength (lbs/sq in) | Min. Edge Crust Test (lbs/in) | Min. Combined Weight of Facings (lbs/m sq ft) | Max Weight of Box and Contents (lbs) | Max Outside Dimensions (L + W + D in) |

|---|---|---|---|---|

| 150 lbs/sq in | 26 lbs/in | 66 lbs/m sq ft | 35 lbs | 50 in |

| 200 lbs/sq in | 32 lbs/in | 84 lbs/m sq ft | 65 lbs | 75 in |

Corrugated Strength Tests

Edge Crush Test (ECT)

Force is applied perpendicular to the edge of the corrugated board until it buckles. The results provide accurate representation of the material’s strength, durability and stack resistance for heavier loads. The resulting value is shown in pounds per linear inch of load-bearing edge and is reported in ECT ratings.

Note: 32 ECT is the most commonly used for corrugated material.

Bursting Test

The burst test, otherwise known as the Mullen Test, challenges the durability of the corrugated fiberboard’s surface. The burst test determines the amount of force required to puncture the liner board. The resulting value is given in pounds per square inch.

Note: 200# means 200 pounds per square inch of force applied to the face of the liner board.